If you’re not a beginner, you can just skim over the top of this. However, thread can be one of the most confusing topics of all time. It’s not a riveting topic to be sure, but essential nonetheless. In addition to this there are a lot of rumors floating around about cotton vs. polyester thread. Polyester is just what it says. Poly, meaning “many” and ester which is a chemical combination. So it is produced synthetically. Cotton is a fiber that grows from the ground. Cotton is spun and then wound to make multiple plies. Multiple threads are wound together. That is what creates single ply or double ply. Like with fabric, each thread can have a different thickness depending on the intended use.

Spools of thread come in different shapes and sizes, and sometimes this can be confusing to beginners. They may think that thread is different in use and composition because the spools look different. Well, sometimes this is true, sometimes not. And, that is confusing. There are spools and there are cones. Many times, cones, the ones that are the large ones in the picture above, are meant for using with a serger or a quilting machine. This is because clearly, they hold more thread. Quilting large pieces requires more thread as does serging a garment. (More about serging later…much more!) Therefore the spool is larger. This doesn’t mean that the thread is some magical, different article.

The weight, or size of thread is something all sewists need to think about from time to time. For the most part and 99% of the time, you are going to use either polyester or cotton thread that is a medium weight, say about a 50 weight or 40 weight thread. Remember the thicker the thread the lower the number. If you’re a nurse, this will make sense to you. You would much rather get an injection with a higher number needle guage, say a 22 rather than an 18. An 18 guage needle is thick! Ouch!

Think of it this way. A thread is labeled 40 wt. when 40 kilometers of that thread weighs 1 kilogram. A 30 wt. thread is heavier because it takes only 30 kilometers of thread to weigh one kilogram, and that’s how those numbers are derived.

There are other classification systems such as Denier and Tex, but for the common, American sewist this information, above, is fine. Many of these have been derived in other countries. Yes, we do buy thread from all parts of the world. If you have any questions, Superior Threads has a very informative website.

When you buy a 30 weight thread, and it’s polyester, it is going to be slightly different than a 30 weight cotton. They will be similar, but not exact.

If you see a spool labeled 30/3, it means that it is 30 weight, and that there are 3 plies, or 3 threads twisted together to make the thread. Most heavy threads are 3 ply.

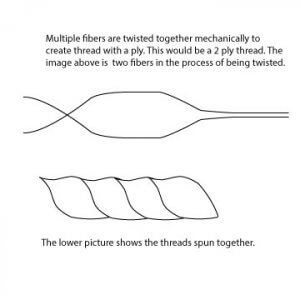

When threads are plied, it increases the strength. Without twisting multiple fibers together, each fiber would pull apart.

Polyester thread is extruded through little holes and then spun, by machines called spinerettes, kind of like a spider! There is a myth out there that polyester thread will tear at the cotton if cotton fabric is sewn with polyester. There was a time when a major thread company disputed this. They called the Fruit of the Loom underwear company. They asked them what type of thread they use, and they reported polyester. They proved that underwear wears out around the area of the abdomen first. In other words, the front of the t-shirts got holes in them but wash after wash, the seams were holding true. Just some fun trivia!

Polyester thread also can come wrapped in cotton. This increases the strength of the cotton. The best thing to do is to experiment with lots of different threads to see which one you think runs smoothly through your machine, makes the straightest stitch and leaves the least amount of lint in your machine.

So, what color should you choose? Well, always test the thread up against your fabric and see what you like. My mother used to say that you should use the color of the background of the fabric. I tend to use a medium gray for just about everything except topstitching or where the thread may show. Gray absorbs the color around it. Black thread is sometimes thread that hasn’t turned out right and so the company over-dyes it. Because of this, the tension on the machine can be tricky. We will discuss tension in another post.

So, for sewing garments, you are going to want to use a 40 or 50 weight thread, either cotton or polyester. If it’s a very fine piece of fabric, such as a shear, you may want to use a 50 weight or higher. For piecing or quilting, a 40 or 50 weight should be fine. Sometimes quilters are so particular about seams laying flat they will piece with a 60 weight thread. Have fun playing with thread. It’s so pretty, it’s all part of the game!